A smart approach to dealing with alarm events and documenting them.

Responsible staff at clinics, practices, pharmacies and laboratories using our electronic temperature monitoring WebLog know it: suddenly, a monitored object triggers an alarm which you would like to simply “click away”. Be cautious, because every alarm has its justified cause. In this article, we would like to explain the “first aid measures”…

First of all, the facts

Medical guidelines require that temperature trends be recorded in environments where medicines are stored.

In your case, this is done electronically using our ICU tech WebLog system, which submits your temperature data to our server, on which they are kept save for at least 5 years. In addition, the temperature monitoring system is triggered by events such as when the temperature exceeds or falls below a set threshold as well in case of communication interruptions.

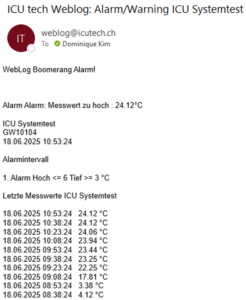

WebLog differentiates between the following messages, which you receive by SMS or e-mail:

- Value too high

- Value too low

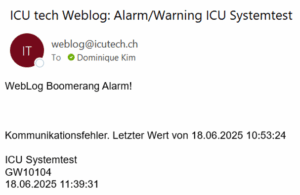

- Communication error

his is how a temperature alarm looks like…

and correspondingly a communication error message…

How do I proceed when…

…value too high / too low?

The first step is to determine whether the message is coming from an appliance, such as a freezer, refrigerator or climate cabinet, or the room temperature monitoring.

In the case of room temperature sensors, it is usually a temperature exceedance, hence the cause can be easily determined asking the following questions:

- is the room poorly ventilated?

- if a room has an HVAC system: is it faulty, incorrectly adjusted or its cooling capacity too weak?

- is a WebLog WLR(H)T sensor (white with slots) inconveniently placed? That is, in a spot with heat accumulation or a heat source.

- or does the sun directly shine into the room or even onto the sensor?

The solution approach can be of a different nature, such as the adjustment or installation of an HVAC system. Repositioning the sensor in compliance with legal and room requirements, with the aim of achieving holistic monitoring, could also remedy the condition. Pro advice: in larger and/or complex rooms structures, it is recommended to place several loggers, we’re more than happy to advise you on this topic.

However, if a freezer, refrigerator or climate cabinet sensor reports an event, the search for the cause becomes more complex and time-consuming. Therefore, we will limit ourselves to the most common causes in this article.

The human factor

Once in a while product packages prevent air circulation, caused by unfavorable loading or even overloading an appliance. If the sensor is enclosed in a niche, the measured temperature may well be several degrees Celsius higher and, in extreme cases, a stuffed appliance may no longer reach the set temperature. Relief is at hand: leave a distance of approximately 5-10 cm between the products and the appliance wall and move products to another device in case of overfilling.

Overcrowded appliances can also prevent the appliance door from closing completely, thus turning into a factor why appliances warm up.

It should also be noted that when filling in larger quantities of (too) little or uncooled products, the refrigerator or freezer’s temperature may rise over a prolonged period of time (several hours!). Therefore, such conditions need to be avoided, because medicines could suffer from a loss of quality and effectiveness.

Technical Factors

On the other hand, there is a whole series of technical pitfalls. Probably the most common occurrence is iced equipment. Ice insulates, a vicious circle develops since the thermostat built into the device never gets to measure the set device temperature, the device constantly tries to reach that temperature. This results in even more ice building up, not to mention the increased energy consumption of the appliance. Furthermore, such situation is not without danger, as the cooling pipes on the back can become boiling hot, this would be problematic when the heat builds up (see also). In such circumstances, the only measure that helps is to completely defrost and dry the device.

Defective door seals should be replaced, as they impair temperature generation. Such door seals can be recognized by cracks in the sealing rubber, also the lack of resistance when pulling the door may indicate reduced tightness.

Household appliances are no-go for medical use. And yes, unfortunately they are also used to store medicines. Such refrigerators cannot guarantee temperature stability and usually show strongly fluctuating temperature graphs on your WebLog app or via https://weblog.icutech.ch

What if communication is lost?

The WebLog temperature and humidity sensors send your temperature data to the GW3 Gateway installed at your facilities, which forwards data to our ICU tech data server. From time to time, a communication error may be reported, the following are the most common causes:

- A sensor has lost its connection to gateway

- The Gateway is offline, i.e. with no connection to the ICU tech data server

- The Gateway is without power supply

Simply acknowledge the communication error and observe the situation. If the error state does not return, it has been a simple short-term interruption.

Should the communication error reoccur, a close look needs to be taken, whereby the following steps should help:

Step 1: Is there a network, internet or even a power outage? In such cases, you would have to contact your technical staff directly.

Step 2: Is a red light visible through the dotted ventilation rack on the back of the GW3 Gateway? If yes, if the device is powered, proceed to step 3. If the red LED is not lit up, plug the gateway in elsewhere, ensure the mini-USB connector on the gateway is well seated. Common cases are defective power outlets or strips, loose contacts and even switched power outlets, by the way, the latter are not suitable for permanent temperature monitoring.

Step 3: Unplug the gateway’s power adapter from the power outlet for about 60 seconds. Since this is a mini computer, doing so is equivalent to a reboot, and can solve a state of unresponsive software. If the device is not back online after 60 minutes, i.e. not up to date temperature values are recorded, please contact ICU tech support.

In summary, it can be said that you should react promptly to any alarm or warning event, as there may be medical products and a lot of money “at stake”. The existence of a clear internal action protocol is essential, no need to mention that all employees should have access to it. An established protocol counteracts staff absences due to illness, holidays, emergencies, etc.

And last but not least, most importantly, acknowledge all events with a comment as soon as you have fixed the cause of the alarm.

We hope this overview serves to make temperature monitoring more efficient and to spend less time troubleshooting.

Should you still need help, please do not hesitate to contact us.